Wood Characteristics & Defects

Wood Characteristics & Defects

We have worked diligently to control the variations in wood as much as is practical to meet your needs for consistency. With our strict lumber selection, we limit extreme variations of color and grain pattern and minimize defects. We further limit the degree of color variation by carefully choosing the finishes available on each wood, and skillfully applying them. What we can not avoid – nor would we want to – are the visual varieties that set wood apart from metal or plastic.

Corner samples work well to show what a given shape, wood, and finish can look like, but inevitably the moulding will differ from the actual sample. Individual corner samples are too small, and it would take too many samples, to show all of the normal variations possible.

Most people know that hardwoods can come with straight or curving grain patterns and will have variation in color within the same species. What the list below describes are characteristics of wood that are relatively common and will routinely show up in your Picture Woods’ moulding orders.

As you read through the lists below, we suggest you look through your samples to find matches to the descriptions. This is a good way to recognize the characteristics and gain knowledge you can share with your staff and customers. If you are interested in obtaining individual chips showing characteristics, please call us. We can send whatever is available.

COMMON WOOD CHARACTERISTICS

The following is a list of some common characteristics found in hardwoods. These characteristics are common, though random, and are evidence that wood is produced from a natural, living thing.

Bee’s Wing & Birdseye – most common in maple. Beeswing is a tight, straight grain pattern with “shimmery” figure perpendicular to the length of the stick.

Birdseye maple, one of the rarest kinds of wood on the planet, has a distinctive pattern. It looks like tiny, swirling eyes disrupting the smooth lines of grain. It is a phenomenon that occurs within several kinds of timber, but the cause is unknown.

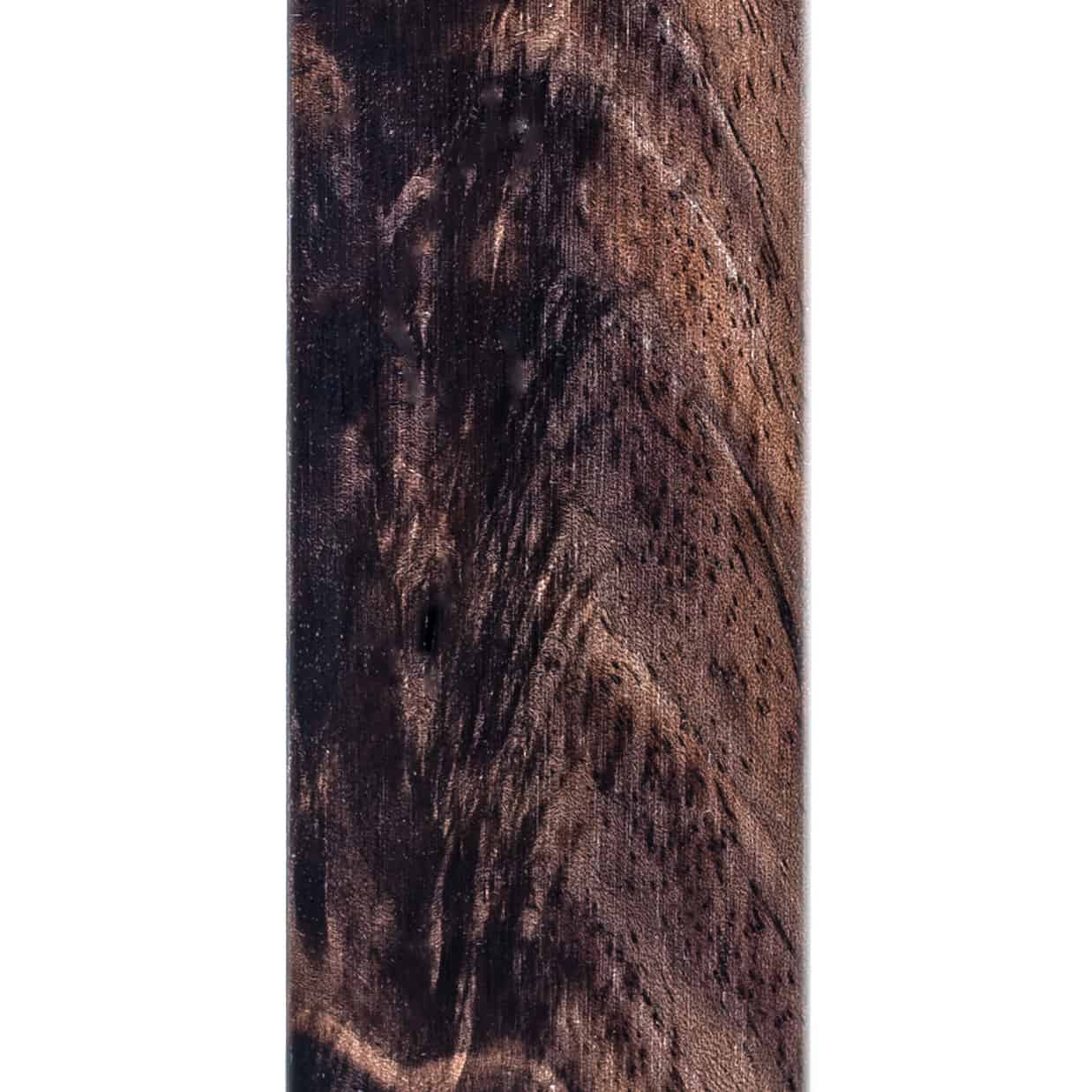

Curly Figure & Burl – possible in any wood.

Curly figure gives the wood a ribboned effect that is perpendicular to the grain. It is created by varying densities within the wood. Also called “fiddleback”.

A burl is a growth on a tree formed from unsprouted bud tissue within the tree. The burl will form large, bulbous looking growths on the base and trunk of the tree. Stress caused by injury, fungus, virus, or insects creates intense grain patterns. Rapid growth in burls also causes further stress and pressure on the wood.

Color Variation – all wood varies from tree to tree and board to board, even after finishing. Some woods change color with age and may arrive lighter or darker than your sample. The most obvious are cherry and walnut. Cherry darkens to a rich, reddish-brown with exposure to light and heat. This darkening can happen quickly (even within a few hours) with exposure to direct light, or over months in ambient light. Walnut fades with exposure to light to a warm, golden-brown.

WOOD DEFECTS

Natural defects occur in all woods. In chops, we cut around them; in length, we deduct “bad spots” footage from the total footage. The following are typical defects in any wood:

Cracks – occur anywhere along moulding, however, they occur most commonly at the ends of a board. We buy only the highest quality, kiln-dried lumber, with minimum cracks and defects

Warp – as a tree grows, internal stresses develop as it overcomes the forces of gravity, wind, and slope of the ground. Stress released as the wood is cut and dried creates warpage. Warpage can be minimized, but not eliminated, by proper drying. We hand-select each board we use and reject boards that do not meet our high standards for straightness. This allows us to produce moulding with minimal warpage. Warpage is considered excessive when a stick bows or crowns more than a usable amount. What is considered “usable” varies based on the length of the stick, the flexibility, and the style of the moulding.